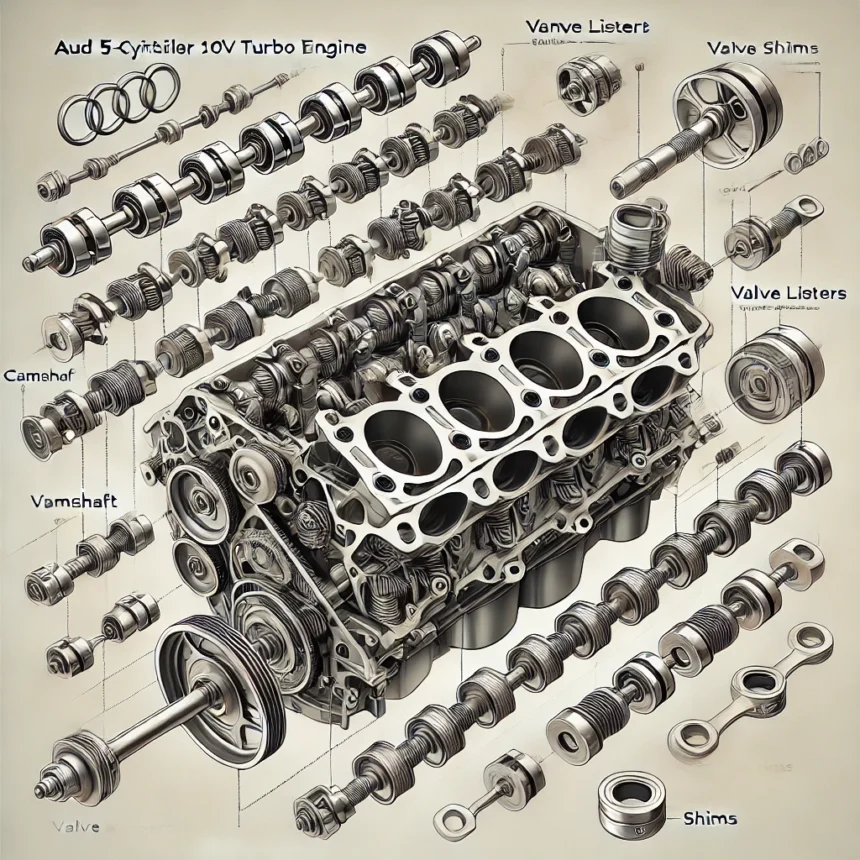

The Audi 5-cylinder 10V turbo engine has earned a reputation for its durability, unique sound, and impressive power output. However, like any high-performance engine, it requires regular maintenance to ensure optimal performance and longevity. One of the most critical but often overlooked aspects of maintaining this engine is ensuring the valve shims are in proper working condition.

Valve shims play a crucial role in maintaining the correct valve clearance, which affects overall engine efficiency, power delivery, and reliability. Over time, wear and tear can lead to improper clearance, resulting in reduced performance, increased engine noise, and potential long-term damage. This article covers everything you need to know about maintaining the valve shims on an Audi 5-cylinder 10V turbo engine, including checking clearance, adjusting shims, and best practices for keeping your engine in top shape.

Table of Contents

ToggleUnderstanding Valve Shims in the Audi 5-Cylinder 10V Turbo

Valve shims are small, precisely machined metal discs that regulate the clearance between the camshaft and the valve lifters. The correct clearance is essential for efficient valve operation.

In an overhead camshaft (OHC) engine like the Audi 5-cylinder 10V turbo, the cam lobes push directly on the lifters, which then open and close the valves. If the clearance is too tight or too loose, it can cause valve timing issues, power loss, and engine damage.

Over time, wear on the valve seats, lifters, and cam lobes can alter the original clearance, requiring adjustments with different-sized shims. Regular maintenance helps prevent premature engine wear and ensures the engine runs efficiently.

Symptoms of Worn or Incorrect Valve Shims

To prevent performance issues and costly repairs, it’s crucial to identify when the valve shims need maintenance. Some common symptoms of incorrect valve clearance include:

Ticking or Tapping Noise

A noticeable ticking sound from the top of the engine is a common sign of excessive valve clearance. This noise is caused by the camshaft lobes hitting the lifters with extra play, leading to inefficient valve operation.

Engine Misfires and Rough Idling

If the valve clearance is incorrect, the engine’s combustion process can be affected, leading to misfires, hesitation, and rough idling. This issue is more noticeable during cold starts and when the engine is under load.

Loss of Power and Acceleration Issues

Improper valve clearance can cause a loss of compression, reducing power output. If the engine feels sluggish or lacks responsiveness, worn valve shims could be the culprit.

Increased Fuel Consumption

When the valves do not open and close at the right intervals, it affects the air-fuel mixture, causing inefficient combustion. This can result in poor fuel economy and higher emissions.

Excessive Exhaust Smoke

If the valve timing is off due to incorrect clearance, the combustion process may not be efficient, leading to increased carbon buildup and excessive exhaust smoke.

Checking Valve Clearance

Regularly checking valve clearance is essential to maintaining engine performance. Audi recommends inspecting the valve clearances approximately every 60,000 to 80,000 miles, but performance enthusiasts who push their engines harder should check more frequently.

To check valve clearance, follow these steps:

- Remove the valve cover – Disconnect any hoses or wires that may obstruct the cover, then carefully remove it.

- Rotate the engine to Top Dead Center (TDC) – Use a ratchet to turn the crankshaft and align the camshaft with the correct timing marks.

- Use a feeler gauge – Slide the gauge between the cam lobe and the shim to measure the clearance. Compare it to factory specifications from the Audi service manual.

- Record your measurements – If any clearances are out of specification, an adjustment will be necessary.

Adjusting the Valve Shims

If the valve clearance is not within factory specifications, the shims will need to be adjusted. Here’s how to replace and adjust them:

Removing the Old Shims

- Remove the camshaft – Depending on your engine setup, the camshaft may need to be removed to access the shims. Make sure to mark timing positions for correct reinstallation.

- Extract the old shims – Use a small magnet or shim removal tool to lift the existing shims from the lifters.

- Measure the existing shims – Use a micrometer to determine their thickness.

Installing New Shims

-

Calculate the required shim thickness – Use the formula:

New Shim Thickness = Old Shim Thickness + (Measured Clearance – Specified Clearance)

-

Select the correct shim – Choose a replacement shim with the correct thickness to bring the clearance back into specification.

-

Install the new shims – Carefully place the new shims in position and ensure they are seated properly.

-

Reassemble the camshaft – If removed, reinstall the camshaft and torque it to factory specifications.

-

Recheck valve clearance – Rotate the engine manually and measure the clearance again to ensure accuracy.

Choosing the Right Valve Shims

Using high-quality valve shims is critical for maintaining proper clearance and preventing premature wear. Always source shims from reputable suppliers or OEM (Original Equipment Manufacturer) Audi parts. Cheap or low-quality shims can wear out quickly, leading to more frequent adjustments and potential engine damage.

Preventative Maintenance Tips

To extend the life of your valve shims and keep your Audi 5-cylinder 10V turbo engine running at its best, follow these maintenance tips:

- Use high-quality engine oil – Proper lubrication reduces wear on the camshaft and valve lifters, helping to maintain proper clearance longer.

- Perform regular oil changes – Old or contaminated oil can lead to increased wear on valve components.

- Avoid excessive high-RPM operation – While the 10V turbo engine is built for performance, frequent high-revving can accelerate valve train wear.

- Monitor engine temperature – Overheating can cause metal expansion, leading to valve clearance issues. Ensure your cooling system is in top condition.

- Inspect valve lifters and cam lobes – During valve clearance checks, examine the camshaft lobes and lifters for excessive wear or damage.

Read also: Bussola to Measure Angles Within a Circle: Leonardo da Vinci’s Ingenious Invention

Conclusion

Maintaining the valve shims on your Audi 5-cylinder 10V turbo engine is essential for ensuring smooth operation, reliability, and peak performance. Regular inspection, measurement, and adjustment of valve clearance will prevent costly repairs and keep your engine running efficiently.

By following these steps and adhering to a routine maintenance schedule, you can preserve the legendary performance of your Audi’s turbocharged 5-cylinder engine for many miles to come. Whether you’re a daily driver or a performance enthusiast, taking care of your valve shims will help you enjoy the power and longevity this iconic engine is known for.